|

|

|

Return to the Hammer B3 Index Page

| Genesis Due to some space constraints and the desire for a larger sliding table I began looking for a replacement for my Delta Unisaw. My search initially led me to consult the Delta industrial catalog but to my dismay I found that the Unisaw is for all intents and purposes the "top-end" of their equipment. I also found this same situation regarding other domestic brands as well as importers like Jet. |

|

| My search then led me to

machines made in Europe. There were several brands imported to these shores to select

from. I eventually settled on the Hammer brand based upon my assumption that it had the

best value for capability and because of it's relatively small footprint. I decided to get

a combination saw / shaper to solve my shop space issues. The dealer configures a machine specifically to an order. I ordered my machine equipped with:

My expectations for the Hammer were derived from a Delta Unisaw

users perspective - in essence, I was expecting a machine that was measurably better than

Unisaw grade equipment in every regard. |

|

| Tablesaw

Function The saw is quite LOUD, much more so than the Unisaw it replaced. I measured the blade flange run-out, it was essentially zero. |

|

| Compared to the jump-start typical

of cabinet saws, the Hammer uses a soft start feature, it takes about 5 seconds to spool

the blade up to operating speed. The saw trunion and motor mount are totally different than what is used on any contractor or cabinet saw design. Basically everything is mounted off of a hinged plate that is bolted to the underside of the iron table by two small bearing blocks. I've noticed that there is some "loosness" in the movement of the trunion when setting an angle. Although the movement isn't as "fluid" as a cabinet saw, I've not experienced any detrimental side effects due to it; angle settings are true, accurate, and repeatable. |

|

|

I had the opportunity to use both the original "triangle" type rip fence as well as the B3L rip fence on this machine. In a nutshell, both are EXCEPTIONALLY POOR and TOTALLY UNSUITABLE for a machine in this price range (or any other for that matter). The triangle type is just down right UNSAFE. For the price and hype of this machine one would expect something of at least average quality and performance but this is not the case. Any of the aftermarket rip fences commonly available are tremendously head and shoulders above the Hammer designs in quality, usability, and performance. |

| The main electrical controls are located on the

front side of the main cabinet. The switchgear is not as conveniently located as those

found on cabinet saws. The main disconnect switch is located on the back of the machine

far away from the main controls. Hammer uses a single removable crank handle for cutter raise / tilt versus the dedicated crank wheels used on competitive equipment. The blade raise function quite stiff and induces some flex in the plastic handle; this imparts a "cheap" image to an otherwise sturdy machine. All other raise / tilt functions work very well with the handle. For blade angle, the resolution is fairly fine at 39.25 turns for 45 degrees. For blade raise the resolution is more course at about 4 turns per 1" of blade raise. The blade raise requires far more effort when compared to a cabinet or contractor saw. Noticeably absent from the saw is a blade height lock. There is a lock for blade angle. I've never experienced any ill effects due to the lack of the height lock so it evidently isn't needed; perhaps this is a function of the effort required to raise the blade to begin with. The table surface is milled, not ground like a typical Delta or even Grizzly; it looks somewhat unfinished but has no detrimental effect in use. My iron table has an area about the size of a hand that is dished down by about 0.007" in the center, otherwise it is flat. The iron table has 15 small diameter holes in it; only five are required for use from the top, the multiple holes looks a little chintzy. Unlike typical cabinet saws, the B3 does not have a leading edge bevel on the iron table. The extension table is made of four thick painted metal sections attached to the rip fence guide rails and supported by a cabinet extension assembled by the user. The metal table provides a sturdy surface however the sections must be individually aligned with the iron table in order for the incredibly inferior Hammer rip fence to slide over them smoothly. |

|

|

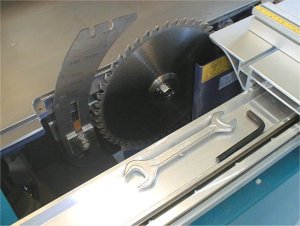

Many of the other Euro saws imported

to the US are equipped with a 5/8" arbor but the Hammer line is not; it uses a

European 30mm arbor which means standard American blades cannot be used without

modification. It is fairly typical of Euro saws not to be able to use a dado blade and

this unit is no exception. Blade changes are actually a little easier than on a typical

cabinet saw. With a 10" blade the maximum depth of cut is 2.75", considerably less than a 10" cabinet saw. With a larger 315mm blade the maximum depth is 4". The blade spins 20% faster than normal due to the line frequency, I think this produces more noise and has a detrimental effect upon the quality of the cut. With a 12"+ blade fitted I noticed a visible "wobble" in the blade which I believe is the cause of the poor crosscutting performance. The 10" blade was rock-solid though. |

| The scoring saw on this machine is

driven via a pulley from the main saw motor. After some setup I found that I could produce

good results. I did not achieve 100% chip-free cuts all of the time but it was certainly

much better than I could have done on a cabinet saw without scoring. The scoring blade width is adjusted by means of three different sized shims that came with the blade. The side to side alignment and blade height adjustments are made via bolts accessed from holes in the saw top. I had expected that the scoring blade raise control would be somewhat inconvenient but have not found it to be so. The maximum diameter main blade with scoring fitted is 10". To use a larger main blade the scoring blade must be removed. |

|

| Shaper

Function The shaper is fairly quiet especially compared to the saw. One unique feature of the Hammer / Felder equipment is the rearward tilting shaper spindle. This feature introduces a capability not routinely found in stand-alone machines. |

|

|

Changing the belt position on a

three-step pulley controls the shaper speed and it is easy and quick to do so. Like the

saw, the shaper is equipped with a soft start and brake function. One major drawback to

the Hammer is that the shaper does not come with a reverse switch. The shaper shares the ON switch with the saw and is located somewhat inconveniently on the front of the machine; however, there is a stop switch that is easily reached on working side of the shaper. The resolution for the angle adjustment is fine at 38.5 turns for 45 degrees of angle. The resolution for spindle raise is fine also at 12 turns per 1" of raise. |

| On my machine the crank handle interferes with the tilting feeder bracket when the spindle is at 90 degrees. This is an obvious design flaw and will cause some inconvenience. Shown in the picture above is a crank extender sent to me later to solve this problem. | |

| I measured the spindle run-out to

be essentially zero. On the ¾" spindle I have, the spacers are 1 15/16" in

diameter, these can limit the use of some small diameter - deep profile cutters. The

center of the spindle is about 6.3 inches away from the sliding table. Both the aluminum infeed and outfeed fences can be offset as well as closed or opened. The faces can be deformed a little if tightened down too much. Overall this is a better than average fence system for a shaper. |

|

| Dust Collection It may not seem like it from the dust remaining inside the cabinet but I estimate that the dust collection is actually getting over 90% of the dust from the saw blade. The goal of a dust-free cabinet is still not achieved; but it's pretty good. The saw guard does improve dust collection measurably with a shop-vac attached and keeps chips from being thrown at the operator. For the shaper, dust collection is acceptable with the spindle set at 90 degrees. With the spindle set at an angle, chips tend to be thrown into the cabinet. The shaper trunion has brushes intended to fill the gaps. However these brushes take a set and when the spindle is moved, the cutter will propel a lot of chips into this gap. |

| Sliding Table and

Outrigger The sliding table is really what makes these Euro machines worthwhile. They have much greater capacity than any aftermarket attachment and operate much closer to the sawblade. On my 78" slider, the cut capacity with scoring is 68". The maximum size piece this unit will crosscut without scoring is 72". The slider is long and can get in the way sometimes, however, I do think the basic format of this type of slider is superior. On the Hammer there is one T-slot track in the sliding table with can be used to attach clamps, jigs, and the standard crosscut fence; this system is superior to the normal miter gauge slots in a cabinet saw or shaper since the whole sliding table can be used as a jig base. The crosscut fence on the outrigger is sturdy, straight, easy to align, easy and fast to remove, and maintains its alignment when removed and replaced. I have found the stop block to be a little disappointing in that it doesn't glide as well as others I've used and the fence clamp handles interfere with the stop clamp knob on occasion. The European sliding table saws are optimized to operate in the "fence forward" position. Although the outrigger table can be positioned elsewhere, the fence (with the outrigger) cannot be positioned in a more American "fence aft' configuration without running into either saw blade access, outrigger support limit, or slider stroke limitations. Without running into any of these limits, the maximum fence aft position yields a 29.5" crosscut capacity (10" blade) or 25.5" with scoring. The outrigger is a pivoting support to hold up the table attached to the sliding wagon. Although the machine can be operated without the outrigger it is very handy when cross cutting sheet goods. Even with a heavy load, the sliding table action is smooth and accurate. |

| Summary The changeover to a European type machine does take some time to get used to but the basic design of the machine is generally superior to traditional stand-alone machines. The Hammer B3 is a much better platform than a cabinet saw could ever be, the only thing that I miss is the ability to use a dado cutter. By including a tilting spindle shaper into the machine, the capability and convenience of this "core" power tool of the woodworking shop is greatly enhanced. The overall fit and finish of the Hammer is roughly equivalent to more common Delta machines, due to the marketing hype I was expecting a little better but in reality, "Delta" class quality is still pretty good. The Hammer uses less plastic and the sheet metal is much thicker and it is generally more robust. Contrasting with that however, is my opinion that the Hammer could have benefited from a little more attention to design detail, especially considering the cost. The following are what I view as the primary high points of the machine:

The following are what I view as the primary low points of the machine:

|