|

|

|

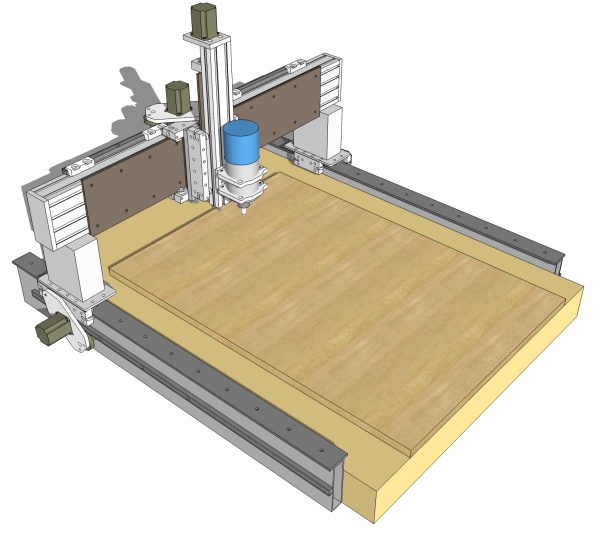

| Introduction This article is a brief introduction to the world of CNC routers used for woodworking applications, primarily at the hobbyist level. CNC is the generic abbreviation for Computer Numeric Control which is generally understood to mean an electronic computer running some form of machine tool through a series of motions controlled by software. For CNC routers this generally means moving a router over material in order to cut or shape it as desired. When first encountering the world of CNC routers, it's very easy to become overwhelmed by all the information available. I would submit to you that at this stage of the game it's rather immaterial if the machine uses stepper or servo motors, whether it's a fixed or moving gantry, what G-code is, and a host of other technical issues that may come into play later. |

|

Initially, ALL of the

technical minutia is subservient to finding out:

|

|

| What can I do

with a machine like this ? First, I would like to point out a very important detail, note that the title of the section isn't "what can the machine do". The tool doesn't do anything on it's own. It may cut very complex patterns but it doesn't come up with the design, select the stock, prep the stock, mount the stock, sand or perform any additional post operations nor does it apply any finish to the material. Of course I'm stating the obvious here but I say it to remind you that in this critical aspect, a CNC router is like any other tool, it doesn't "create" anything on it's own. |

|

| More so than other typical

shop tools, this is a "game-changer" tool. By that I mean that this tool

can open up a whole realm of possibilities that could have been out of reach previously.

It's not that one could not accomplish the same task through the use of a different tool

or technique, it's that it will allow you to accomplish (dare I say "master")

the task in far shorter order. Obviously, if something is easier to accomplish, it's much more likely to get done. Effects such as carvings, inlays, curved cut-outs & profiles, and many more complex or tedious operations can be performed much more easily with a CNC router. If it's easier to do, you are likely to incorporate it into your projects more often, it's just that simple. So what can you do with a machine like this? There is no simple answer because your imagination is the only limitation. |

|

| What does it cost

to get into the game ? The "entry fee" to this realm varies. It depends upon your inclination, skill, and how much you want to spend or learn how to do. Your wallet will likely dictate whether you can play the game at all or where you must enter into it. There are a few hobbyist level systems out there, plan on spending about $3k for the likes of a low end Compucarve. For a more capable and reliable desk top machines you'll be in for about $4k. Purchased machine prices start to escalate quickly from thereon. An even more capable ShopBot Buddy is going to start at a bit over $7k for instance. The numbers quoted above are fairly simplistic but if you ain't got a wad in your wallet, it doesn't much matter. Once you get past that, you might also consider cost per cutting volume. In that case, you will find that the less capable and "cheapest" system(s) are actually the most expensive. For example, the ShopBot costs about $2k per cubit foot of cutting volume, the Compucarve is about three times that! |

|

| In addition to buying a

machine there is another option however and that is to build your own. Yes, it's entirely

possible to build your own CNC system. Even though they are easily 10 times more

sophisticated than a typical shop tool, it's possible to make one yourself.

Parts and software are readily available as are plans for several different machines.

Should you go this route, expect to put in somewhere between $2k - $4k as well as some

considerable time designing and building the machine. However, considering that most woodworking hobbyists do not even own a $2k cabinet saw, you can easily surmise that $3k, $4k, and $7k is a bit out of reach for most woodworkers. Unfortunately, that's what it costs though. |

|

| What

type of skill does it take to successfully run the system ? So even if you desire to have the capability and you can afford to get into the game, you may ask, "do you have to be a rocket scientist to run the thing"? Time for some good news. Anybody with an average ability to use a computer and is only a little graphics software savvy can learn to use the most popular CAM software fairly quickly. The more experienced you are with computer software, the easier it will be for you. Anybody that knows how to use a router can easily understand the concept of tool paths that the CAM software creates. After that, it's just like learning any other woodworking tool, in fact, it's easier than some. |

|

| Summary So there you have it. If you're still interested in getting into the game you can focus on buy versus build questions, cutting capacities, the different technologies used and everything else. To summarize the above: 1. A CNC router will allow you to do incredible things, your imagination is the only real limitation in it's use. 2. The entry cost is relatively high. 3. Just about any computer literate woodworker can learn to use the tool. If you consider carefully the text above, you will realize that cost is probably the primary issue to deal with. |