|

|

|

| The Debate Every so often a debate will develop on the internet regarding whether CNC has any place in the craft and by association, whether those who use them are true craftsmen or not. These discussions usually take place on woodworking forums or other craft oriented sites. They don't occur on commercial oriented sites because business owners care most about profits and other issues and far less about one's "personal journey". In a commercial environment, this is a laughable "debate". |

|

| I've read through my fair share of

these discussions and offer the following view points. First, so far as I have seen, those

most ardently opposed to the use of CNC in "fine woodworking" are those that

have never owned a CNC machine. The old saying "it's easy to degrade what you do not

understand" seems to be applicable here. Let's look at this discussion on it's

technical merits though. I won't divert into what

"cheating" means. The main gist of the matter is that some people think

the the use of a CNC tool degrades the craft or in some way makes the end product less

worthy than if it were made by some other more manual method. |

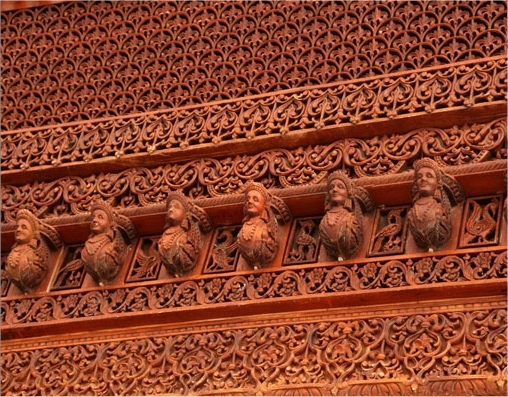

| Craftsmanship Let's look at "craftsmanship" a little closer, what exactly does that mean anyway. Does it mean that one is only considered a "craftsman" if a carving is done 100% using hand-held chisels? Does it mean that a power tool also qualifies but only if it is guided 100% "by-hand"? I guess that would leave guide bushings, bearings, and templates out then huh? If either of these are true, anyone who uses a common power planer is then NOT a "craftsman". A board is fed in at one end and it comes out smoothly planed and perfectly thicknessed out the other, all without any human hand guiding anything. A CNC router isn't even automated as much as this. Does it matter if the same board were hand-scraped etc afterwards, NO; the automated machine did most of the work. The exact same could be said of any power feeding operation. |

|

|

At this point some might argue that

power tools are only used to relive the "tedium" or more laborious aspects of

the work whereas a CNC machine does something else. Not so, I would also find it

pretty "tedious" and labor intensive to do by hand most of what I've done with

my CNC machine, where is the difference? In order to use a CNC machine from design to cut, several new skills must be mastered. This alone constitutes a certain level of craft that must be acknowledged. Just like many hand skills, learning the "craft" never really ends. |

| Summary It's important to note that the "debate" such that it is, is only among peer groups. Recipients (other than ourselves) of the end product hardly care a twit whether something was cut with a chisel or a CNC router. They do care about getting what they want, quality, and time (cost). It's also important to note that those that bemoan the use of CNC tools are logically compelled to also decry the use of other power tools; in for a penny - in for a pound. So unless you use hand tools exclusively, railing against CNC's is blatantly hypocritical. I personally admire anyone who has the skill to carve by hand, cut inlays by hand, etcetera. I know that I don't have the time to master those skills by hand. I also envy the relative peace that comes from not having to hear a power tool run. On the flip side I don't regard the countless hours of chip making as intellectually rewarding. I would rather spend my time in the more rewarding design aspects. That is what a CNC router allows me to do, focus on the design and implementation in order to get something done; it's just that simple. In the end, a CNC router is just like any other tool in the shop, it doesn't create anything on it's own, it takes a "craftsman" to make that happen. |