|

|

|

|

The Ridgid TS3650 has a two inch

dust collection port built into the cradle design. Part of the schroud is made of

cast iron and integral to the cradle, the other part is a plastic molding that has the

actual hook-up. When the saw was introduced, there was a lot of discussion about the size of the port. Some people felt that it was too small and would jam with small cut-offs. Before I began this modification I already knew that this "jam" problem would exist even with a 4" port as I have one this size on my Hammer B3 saw. |

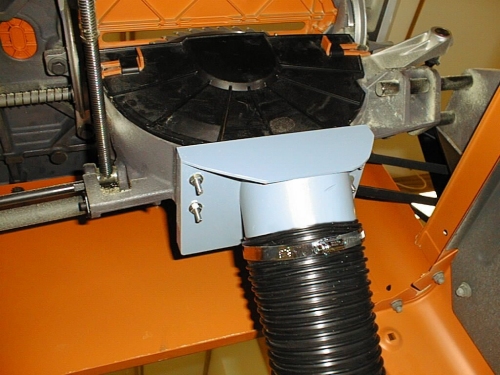

| In any event I was curious about the prospect of mounting a larger port to the TS3650 anyway and after some thought I designed a modified port connection. In order to put a 4 inch hose onto the machine a new hook-up must be made, this is far easier than modifying the existing part to accept this size of hose. The new port consists of a flat plate in which an angled section of 4" PVC S&D pipe is inserted. The dimensions of this part were determined by trial and error as well as by the OEM plastic part being replaced. I used 3/4" plywood for the attachment plate. |  |

| I used automotive epoxy to glue the PVC to the plywood. The hole in the plate was drawn using the angle-cut PVC as a guide. It was roughed out and sanded to the proper size and angle using a rotary rasp (shown) in a cordless drill. Note that the plywood is oversize during the assembly stage to make it easier to cut the appropriate holes and such. | |

|

The original mounting

holes were used but a longer thread was needed to accommodate the thicker material.

The Ridgid has pretty good access to the bottom of the table so fitting up and working on

the machine for this modification is not particularly difficult. The best time to do

this modification would be during initial assembly though. Due to the extreme angle of the PVC pipe, it is truncated at its far edge, it would hit the saw cabinet sidewalls if it was not. Also, to account for a larger opening, a cover plate (shown here as 1/8" hardboard) is used to block off an air leak opposite the blade shroud side. Note the two routed slots to accommodate the blade cover plate tabs. The original DC hook-up is shown here for comparison. Instead of the original screws, studs were used to attach the new port to the saw.

|

| Even though I made one of these, I don't really consider it to be a tremendously worthwhile project; the saw works fine without this. I am sure that it does have better collection but still does not (as expected) eliminate the pipe from being jammed with off-cut slivers, a zero-clearance throat plate does far more to eliminate this problem. It doesn't take long to make this part, I spent more time deciding how to do it. | |