|

|

|

BT3100 Rip Fence Alignment

| Goal: | The rip fence

should be as straight as possible. It is almost pointless to align the rip fence

unless it is straight and this should be checked first. Using a straightedge, it

should be checked for no gaps greater than 0.002". Any bow will cause cut

quality to suffer. The rip fence should be aligned as close to parallel to the blade as possible. The face of the rip fence should be perpendicular to the table. This isn't critical for rip cuts but could be important if jigs use the rip fence. The angle is controlled by the rip fence rails but the rip fence glide pads could be shimmed to compensate as well. |

|

| Tolerance: | The rip fence should be within +/- 0.004" (over the blade distance measurement) of parallel. | |

| Error Effect: | If the fence

is out of tolerance by a small amount, one face of the rip cut will have slightly fewer

saw marks and the other will have slightly more. The cut edge will be a very slight cove,

so slight that it will be difficult to observe (on ¾" thick stock). If the fence is out of tolerance a little more, the cove will be greater (still hard to observe), there will be excessive saw marks, and perhaps more chip-out on the cut. The riving knife (if fitted) may start to have an influence on guiding the cut and the rip may not be straight. If the riving knife is not fitted, the blade will start to auto-guide the cut. If the fence is angled away from the blade, the blade will guide the rip slightly away from the fence at the back. If the fence is not particularly close to parallel, there is great risk of kickback, particularly if the fence is crowding the blade (angled towards it). This should be the point where the riving knife is preventing serious injury. |

|

| Process: | Unplug the saw for safety. Unfortunately, the rip fence's alignment mechanism is fairly crude compared to most other saw fences. To align the fence, two screws in the top of the fence must be loosened, (the fence lever is unlocked), and the fence moved to alignment, and the screws re-tightened then the fence is locked down. In case this isn't obvious, it is difficult to move a machine feature precisely without some sort of high resolution aide. Many rip fence systems use some sort of fine pitch screw to set the fence angle, the BT3100 does not. | |

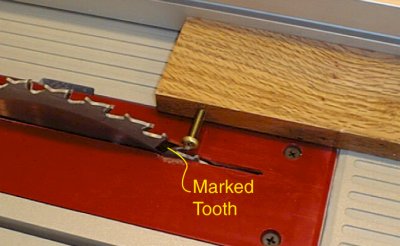

| A jig will be used to measure alignment. The jig is nothing more than a block of wood with a screw threaded into it. This jig and technique is as old as the hills and remarkably accurate. Other more sophisticated equipment could be used but this does the job very well and costs nothing. |  |

|

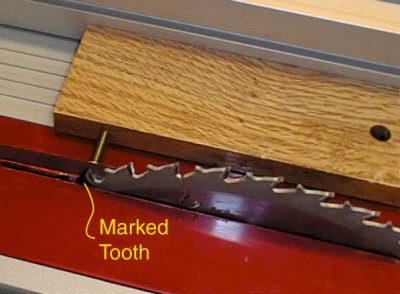

| To measure alignment, raise the blade ALMOST to it's full height. The reason not to raise it fully is that quite often some mechanical anomaly exists at the extreme end of a mechanical movements; this would influence alignment measurements. After the blade is raised, mark one blade tooth for reference. Using one tooth for the measurements will provide more accurate readings. Using the jig shown, move the rip fence to allow the screw head to be close to the marked blade tooth and then adjust the screw so that it barely makes contact with the tooth, this is the initial reference or "zero" point. | ||

| Now rotate the blade back and place the jig adjacent to the same marked tooth. If the fence is very close to parallel, the contact between the screw and tooth will make the same sound. If this is so the fence is parallel. If there is a gap, the fence is angled away from the blade. To measure the gap, use a set of feeler gauges. The one that fits between the tooth and the screw is the amount of misalignment (over the measured distance). If the screw head projects past the tooth, the fence is angled towards the blade. |  |

|

| If a feeler

gauge greater than 0.004" fits between the gap, one should attempt to align the fence

better. If the fence cannot be set parallel, it would be slightly better to have the error

with the fence angled away from the blade on the side it is normally used (to avoid the

"trapped cut"). Ideally, the rip fence will hold it's alignment as long as the BT3100 rip fence rails have not been moved. If they are moved, alignment should be re-checked. Ideally the rip fence can be repositioned and it would still hold the parallel alignment within some very small tolerance. |

||